Oil Mist Delivery System for Spindle Bearings

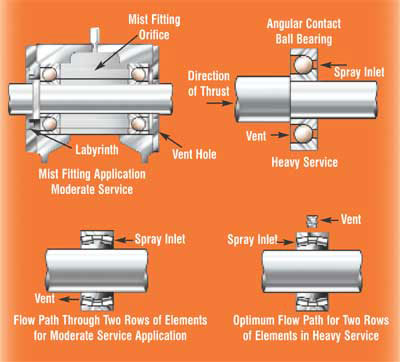

An oil mist delivery system is a device used to lubricate spindle bearings in machine tools. The mist is made up of a mixture of oil and compressed air. This admixture is continuously fed to the spindle, which increases the internal pressure in the bearing.

Modern oil mist systems are virtually tamper-resistant due to their improved system design. They also use hermetic bearing contact seals to eliminate stray mist, which is a problem with older systems. Moreover, oil mist generators are equipped with micro-process control, which allows them to achieve precise mist control based on ambient conditions.

The oil mist delivery system uses a piping system and a special mixing block to deliver oil to the bearings. Once the oil has reached the bearing, it is recovered by a vacuum system and recycled. This system is available for existing spindles as well as new ones. New spindles are designed with provisions for oil-mist or air/oil reclamation systems. The type of system used determines the conversion process.

Oil mist delivery systems are becoming popular in different industries, including steel mills. Oil mist units are available in compact units for local applications. Some steel mills have started using air/oil systems as an alternative to oil mist. The air stream carries liquid oil in a spiral motion, which enters the bearing as an oil spray.

- Previous: How to Lubricate Spindle Bearings

- Next: Lathe Spindle Bearing Size Chart