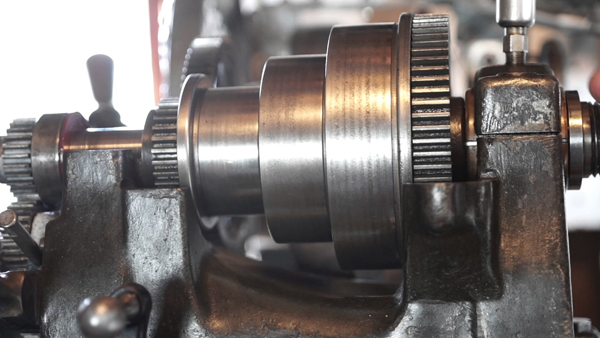

Lathe Spindle Bearing Size Chart

A lathe spindle bearing is a component that turns a lathe's spindle. It comes in many sizes and types. Some are angular contact ball bearings, while others are cross-tapered roller bearings. Both types have unique geometry and are generally used in rotary applications.

Spindles are critical parts in machine tools because they help shape materials through high-speed rotation and pressure. As a result, manufacturers invest in high-quality bearings for these machines. High-quality bearings will increase the efficiency and reliability of machine tools. In addition to allowing machines to rotate at high speeds, high-quality bearings will also ensure a longer bearing life.

The most common type of spindle bearing is the angular-contact ball bearing. This type of bearing consists of one or more rows of rolling balls that engage a concentric grooved ring. The angle at which a load contacts the bearing determines its axial load capacity. The greater the angle, the more axial load capacity it can carry. Another type of spindle bearing is the radial bearing. This type of bearing is comprised of two ring housings that are filled with rolling balls. This type of bearing is ideal for industrial machinery and is capable of carrying axial and radial loads.

- Previous: Choosing and Maintaining a Thrust Ball Bearing Assembly

- Next: Lathe Spindle Bearing Replacement