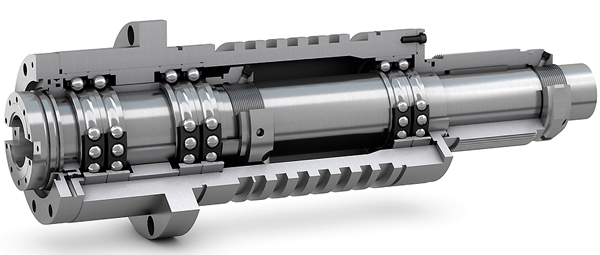

What Is a Ball Bearing Spindle?

A ball bearing spindle is a mechanical device that is made of ball bearings. Ball bearing spindles have several types. These types include angular contact, radial contact, and combined bearing sets. Some types are rigid, allowing only minimal overturning clearance. Other types can be flexible, allowing some overturning clearance.

Angular contact ball bearings

The benefits of angular contact ball bearings are obvious, but choosing the right one for your specific application isn't always straightforward. For example, your application may require a higher load carrying capacity, but you don't necessarily want to sacrifice maximum speed. Luckily, there are angular contact ball bearings that satisfy both needs.

Compared to deep groove bearings, angular contact ball bearings can withstand greater axial loads and can limit axial displacements. The key to choosing a suitable bearing for your application is to consider the tilt angle between the inner and outer rings. If possible, choose a bearing with a smaller angle, as a smaller angle will give you better radial capacity. But if you need higher rigidity, choose one with a larger angle.

Angular contact ball bearings are used in main spindles for machine tools and are used to support axial forces. They can be used in single rows or in multi-bearing arrangements. In addition, single-row angular contact ball bearings can be preloaded to increase their rigidity. They are commonly used in machine tools where high running accuracy is essential. These bearings typically feature cages made from pressed steel or molded resin. However, in some applications, cages made from machined brass or specialized polyamide resin are used.

Angular contact ball bearings are also available in double-row designs. Double-row bearings are similar to single-row versions, but are narrower and can withstand higher radial and axial loads. They can also absorb tilting moments.

- Previous: Choosing High Speed Spindle Bearings

- Next: CNC Spindle Bearings