Home / News / The Basics of Precision Angular Contact Bearings

The Basics of Precision Angular Contact Bearings

High-speed grinding spindles require precision angular contact bearings that can handle both radial and axial loads. These bearings are available in ABEC7 and P4 grades. In this article, we'll look at what the differences are between these two types of bearings, how to clean them, and how to properly store them.

ABEC7 or P4 precision angular contact bearings

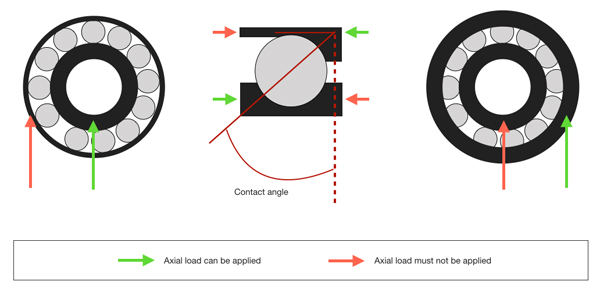

Angular contact bearings have a unique design that allows for a contact angle between the ball and the races. An axial load passes through the bearing in a straight line while the radial load takes an oblique path, creating a contact angle. Besides the axial load, there is also a thrust load that causes the balls to move in an angular direction. Both types of loads are balanced through a preload, which can be applied to the bearing during manufacturing or once the bearing is installed in the application.

ABEC7 and P4 bearings are designed for extreme accuracy and are able to withstand high temperatures and mechanical stresses. They are available in high precision and a range of designs. Generally, a DB bearing has a radial profile, while a DF bearing has a fractured raceway.

High-speed grinding spindles require precision angular contact bearings

Precision angular contact bearings are a critical component for high-speed grinding spindles. These bearings offer high load carrying capacity and speed, as well as precise positioning. They are also extremely rigid even at high speeds, making them an ideal choice for high-speed machines.

Most high-speed grinding spindles use high-precision hybrid ceramic ball bearings, which typically have an accuracy rating of ABEC 7 or 9. They can support axial and radial loads. They may be pre-loaded to achieve a desired maximum speed, and lubrication may be via a simple grease or more complex oil-air injection system.

Angular contact bearings are designed for radial and axial loads

Angular contact bearings are radially and axially balanced and have three important operating specifications. The first is the rated speed, which is the maximum speed at which a bearing can work without permanent deformation. The second is the radial load, which is a calculated, constant radial load that a group of identical bearings can tolerate in theory for one million revolutions of the inner ring.

Precision angular contact ball bearings are designed to transmit forces at a specific contact angle. The greater the contact angle, the higher the axial load carrying capacity of a bearing. Because of this, angular contact bearings are ideal for applications with high axial and radial loads.

Cleaning and storage of precision angular contact bearings

When it comes to cleaning and storing precision angular contact bearings, you need to be extremely thorough. You must remove the bearing's protective shield to allow for thorough cleaning. This shield protects the cage and balls. The shield is usually made of metal and is held in place by a c-clip.

Cleaning and storing precision angular contact bearings is a vital part of maintaining the high-performance of these bearings. High-precision instruments and components require flawless bearings to work effectively. These tools are used in a variety of industries and require regular maintenance and parts replacement. If you are in need of a replacement part, Angular Contact Bearings can provide you with an affordable solution. In addition to offering ready-to-install precision angular contact bearings, they also provide onsite technical support, which means you'll be able to work with confidence knowing that your bearing is performing at its highest level.

Application of precision angular contact bearings

Precision angular contact ball bearings are used in a wide range of machine tool applications. The requirements for these bearings vary, depending on the machine tool. Lathe spindles, for example, usually cut metal at very slow speeds, whereas milling machines need high load carrying capacity and rigidity.

Precision angular contact ball bearings are available from NSK in a variety of designs and materials. They are ideal for applications that require high runout accuracy and high rotating speed. The range of NSK bearings includes basic series meeting ISO standards, as well as specific series for machine tools. There are also sealed angular contact ball bearings that come pre-lubricated.

- Previous: Dimensions and Application of Single and Double Row Deep Groove Ball Bearings

- Next: Advantages of a Super Precision Angular Contact Ball Bearing