Home / News / Spindle Bearing Preload Adjustment: Importance, Methods, and Best Practices

Spindle Bearing Preload Adjustment: Importance, Methods, and Best Practices

Introduction

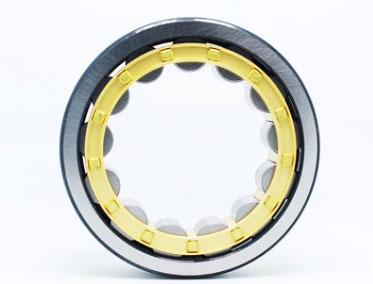

Spindle bearing preload is a critical factor that affects the performance, accuracy, and longevity of spindle bearings in various types of machinery, such as CNC machines, milling machines, and lathes. Proper preload adjustment ensures optimal bearing stiffness, reduces vibration, and minimizes heat generation during operation. This article will discuss the importance of spindle bearing preload adjustment, the different methods used to adjust preload, and best practices for achieving optimal bearing performance.

Importance of Spindle Bearing Preload Adjustment

Bearing Stiffness

Proper preload adjustment provides the desired bearing stiffness, which is crucial for maintaining high accuracy and precision in machining applications.

Reduced Vibration

Optimal preload reduces vibration during operation, minimizing noise and improving the overall performance and surface finish of machined parts.

Minimized Heat Generation

When spindle bearing preload is correctly adjusted, the heat generated during operation is minimized, reducing the risk of thermal expansion, which can cause a loss of accuracy and potential bearing damage.

Methods of Spindle Bearing Preload Adjustment

Spring Preloading

Spring preloading involves the use of springs or wave washers to apply a constant force to the bearing assembly. This method allows for easy preload adjustment and accommodates thermal expansion during operation.

Fixed Preloading

Fixed preloading is achieved by using spacers or shims between the bearing components to set the desired preload. This method provides high stiffness and accuracy but may require additional adjustments to account for thermal expansion or bearing wear.

Adjustable Preloading

Adjustable preloading uses a threaded nut or collar to apply the preload force, allowing for easy and precise adjustments. This method is particularly useful in high-precision applications where fine-tuning of the preload is necessary.

Best Practices for Spindle Bearing Preload Adjustment

Follow Manufacturer's Guidelines

Always refer to the manufacturer's guidelines for recommended preload values, as these are based on the specific bearing design, size, and application requirements.

Maintain Cleanliness

Ensure that the bearing components, tools, and workspace are clean and free of contaminants during preload adjustment to prevent premature wear and failure.

Use Proper Tools and Techniques

Utilize appropriate tools and techniques to adjust the preload, ensuring even and accurate force application and preventing damage to the bearing components.

Monitor Bearing Performance

Regularly monitor bearing performance, such as temperature, vibration, and noise, to identify any potential issues related to preload adjustment. Adjust the preload as necessary to maintain optimal bearing performance and extend service life.

Regular Maintenance and Inspection

Perform regular maintenance and inspection of spindle bearings to identify and address any issues related to preload adjustment, wear, or contamination. This will help maintain optimal bearing performance and extend service life.

Conclusion

Spindle bearing preload adjustment plays a vital role in the performance, accuracy, and longevity of spindle bearings in various types of machinery. By understanding the importance of spindle bearing preload adjustment, utilizing the appropriate methods, and following best practices, you can achieve optimal bearing performance and extend the service life of your machinery. Always consult the manufacturer's guidelines and consider seeking professional assistance if you are unsure about any aspect of spindle bearing preload adjustment or maintenance.

- Previous: Spindle Bearing Grease: Selection, Application, and Maintenance

- Next: CNC Spindle Bearings: Types, Selection, and Maintenance