Crossed Cylindrical Roller Bearings

Crossed cylindrical roller bearings are designed to eliminate the need for separate outer and inner rings, simplifying structural design. Crossed cylindrical roller bearings find applications in precision rotary tables, industrial robots, and IC manufacturing. Our company manufactures standard and non-standard bearings with IDs ranging from 80mm to 1250mm and can achieve P5 levels of accuracy. Here are some features of these bearings:

feature

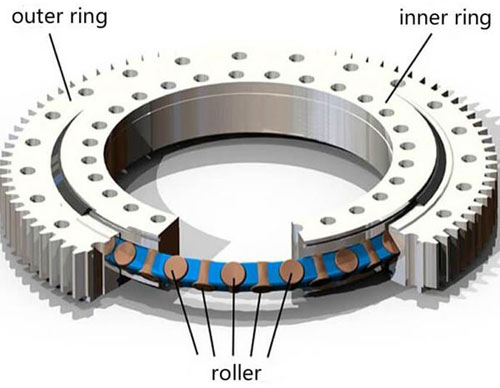

A cross cylindrical roller bearing is a type of bearing that consists of two circular rollers that are perpendicular to each other. These bearings feature a split outer ring and a single inner ring. They are manufactured by Austin Engineering Company Limited, an ISO 9001:2008-certified manufacturer located near Junagadh, Gujarat State. Founded in 1973 by five technocrats, Austin Engineering Company Limited has grown into a worldwide manufacturer of precision bearings. With an effective global delivery network, Austin Engineering Company Limited delivers quality products with shorter lead times.

Another feature of cross roller bearings is their minimal miniaturization. Their ultra-thin structures are close to the limit of the small-sized ring type. They are ideal for rotating parts in industrial robots and machinery processing centers, as well as precision rotary worktables and medical and measuring instruments. During the IC manufacturing process, these bearings are widely used. Hence, they are a popular choice for precision rotating worktables in IC manufacturing equipment.

catalog

Crossed cylindrical roller bearings are bearings with a single axial axis. They are available in a variety of diameters and load carrying capacities. These bearings are commonly used in precision devices, medical equipment, industrial robots, aerospace, and more. The following is a summary of the different types of crossed roller bearings and their characteristics. The following is an overview of the basic rating life, load carrying capacity, and additional safety factors.

This bearing type features a compact design construction and rollers that alternately cross between an outer ring and an inner ring. It can take both radial and moment loads. Typical applications for crossed roller bearings include industrial machinery, construction machinery, medical equipment, and industrial robots. These bearings are manufactured for precision alignment of parts and components. The following characteristics make crossed roller bearings ideal for a variety of applications.

diameter

The Diameter of crossed cylindrical roller bearings is the size of the cylindrical rollers that rotate in a bearing unit. They can come in various sizes, such as slim, high rigidity, and standard. In addition, they can be obtained in different diameters and widths. In some applications, they can be mounted via a mounting hole. If you want to mount a crossed roller bearing on a shaft, you can request for a special flange.

Crossed roller bearings are used for high-precision applications, as they can carry both axial and radial loads. The 'O'-shaped design of the crossed roller bearing allows it to transmit tilting moments without worrying about the direction of loads. Compared to angular contact ball bearings, their space requirement is significantly reduced. They can also be used for smaller spaces, as the cross sectional area of the rear mounted bearing is half that of the 'O'-shaped type.