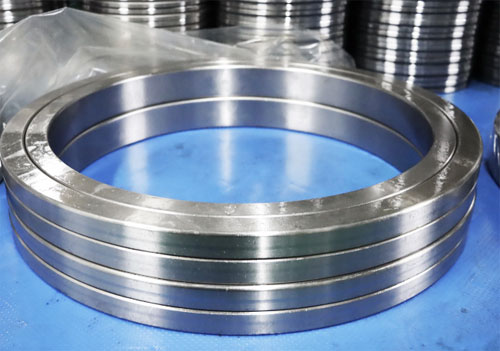

XR Series Crossed Tapered Roller Bearings

You may have heard of Four-row and Double-cup tapered roller bearings but did you know that there are also XR Series crossed tapered roller bearings? There are several differences between these bearings and understanding these differences is important when choosing the right one for your application. In this article, we'll discuss the differences between these bearings and how they can benefit you. Let's get started! Firstly, what is a crossed tapered roller bearing?

Four-row tapered roller bearings

Like their cylindrical counterparts, four-row tapered roller bearings are designed to withstand extreme combined loads. The higher the contact angle, the greater the axial load capacity. Their four-row configuration ensures optimum load distribution. If the operation is prone to contamination, sealed four-row tapered roller bearings are highly recommended. NSK offers a range of four-row tapered roller bearings in various special materials. The bearings are ideal for rolling mills.

Four-row tapered roller bearings can be customised to meet the specific requirements of the application. The design and lubrication of the bearings can be altered to suit working conditions. They can be fitted with different spacer ring thicknesses or pierced rollers. These four-row tapered roller bearings can be relubricated via their outer or inner ring. Listed below are some of the common features of four-row tapered roller bearings.

Double-cup tapered roller bearings

Tapered roller bearings have unique design characteristics. They feature angled raceways and two separate cones that fit into a single cup. The cage separates the rollers to maintain a fixed distance. This ensures smooth rotation and even load distribution. In addition, double-cup tapered roller bearings are commonly used in hoisting equipment. Double-cup tapered roller bearings are used in hoisting equipment and gearboxes.

Double-cup tapered roller bearings have two grooves along the outer raceway. The inner raceway consists of two separate cones separated by a spacer. Double-cup tapered roller bearings are most commonly used for heavy machinery. Double-cup bearings are similar to single-row tapered roller bearings, but they are a specialized type. They are used where two or more rollers are needed for high loads.

XR Series crossed tapered roller bearings

XR Series crossed tapered roller bearing combines two tapered roller bearing functions in one unit. These bearings have high rigidity and rotational accuracy, allowing them to support high loads. They are preloaded, making assembly a faster process and minimizing shaft thermal expansion. In addition, they support radial, axial, and tilting loads. Unlike conventional roller bearings, cross tapered roller bearings have two separable outer and inner rings that can withstand high loads.

Unlike traditional cylindrical roller bearings, crossed tapered roller bearings offer superior radial and axial performance. They are also ideal for applications that require high speed and low friction. They can handle high radial and axial loads and are designed for applications with limited space. These bearings are extremely durable, and are used in many different industries, including cement plants, paper mills, and oil companies.

- Previous: Crossed Cylindrical Roller Bearings

- Next: crossed tapered roller bearings