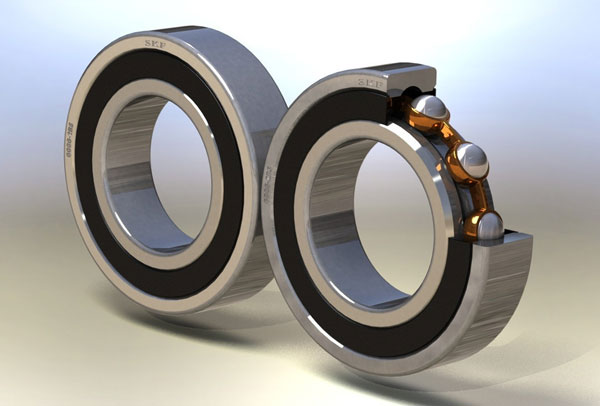

Single Row Deep Groove Ball Bearings

When choosing a single row deep groove ball bearing, you may be faced with a few difficult choices. For the sake of this article, we will discuss some of the important factors you should look for in a ball bearing. These include Dimensional accuracy, Load carrying capacity, Noise level, and Standard cages. We will also discuss the benefits of double-lip seals, which are great for retaining grease, moisture, and dirt.

Standard cages

Besides the standard cages for ball bearings, there are also metric series for bearings. Among them is the 69 Series, which can be either open, shielded, or sealed. The latter is produced in various combinations. The former is suitable for high-speed operation, whereas the latter is suitable for low-speed operation. Moreover, the 6908 Thin Section Deep Groove Bearing is available in an open, shielded, or a sealed design.

Load carrying capacity

To determine whether a bearing is suited for a particular application, it is necessary to know its load carrying capacity. Single row deep groove ball bearings must have enough load carrying capacity to prevent slipping. To prevent slippage, a bearing must have a minimum radial load of P>C0r/100. Usually, however, the actual radial load is higher than this requirement.

Dimensional accuracy

Single row deep groove ball bearings are one of the most popular types of rolling bearings because of their durability, versatility, and ease of maintenance. They are also very economical, making them some of the most widely used types of bearings in the world. Schaeffler manufactures single row deep groove ball bearings in a variety of sizes and designs. They also offer Generation C bearings, which feature noise-reduction technology.

Noise level

Single row deep groove ball bearings are the most common type of bearings. They feature self-retaining, solid outer and inner rings and ball and cage assemblies. Due to their low friction torque and solid design, they can withstand high radial loads and small axial loads. However, excessive axial loads can lead to high noise levels and reduced bearing life. To determine the noise level of single row deep groove ball bearings, you need to know their specific characteristics.

Applications

Single row deep groove ball bearings are self-retaining units that feature a solid outer and inner ring and no filling slots. The cages for these bearings are typically made of brass or polyamide PA66. They are also available as open bearings with turned recesses. Single-row deep groove ball bearings are available with different load ratings and speeds. The main differences between these two types are their size and materials.