Longer lifespan deep groove ball bearing

Sealed deep groove ball bearings are popular with manufacturers of industrial equipment because of their higher load-carrying capacity. They have the added benefit of low friction coefficient and require minimum maintenance. In addition, these bearings are highly economical. Read on to learn more about these types of bearings. You can choose the best deep groove ball bearings based on your requirements. We have listed the benefits of deep groove ball bearings below.

Sealed deep groove ball bearings

The longevity of sealed deep groove ball bearings is closely related to the material used to manufacture them. Sealed deep groove bearings are composed of synthetic rubber, while low friction ones contain oil and sheet steel reinforcement. Both types of deep groove bearings can operate over a wide temperature range. A large shielded deep groove bearing lacks a cylindrical section, but has a long sealing gap. This type is often used for applications involving rotation of the inner ring.

Ceramic balls

Consumers who are looking for a durable bearing should consider investing in a ceramic deep groove ball bearing. Ceramics are a superior material, with a longer lifespan, and lower friction than metal ball bearings. A deep groove results in more stable balls, which are ideal for skateboarding. They also have the advantage of a lower friction coefficient, limiting noise and vibration. Additionally, they provide some axial load capacity.

Electrical insulation

In the NKE manufacturing facility, insulating layers are applied on both the inner and outer rings of the bearings. The insulating layer is made of thin-film technology, and plasma spraying is used to apply the coating. The insulating layer consists of an oxide ceramic coating, which is applied at high velocity to the outer ring surface. The outer ring is sealed to prevent moisture from penetrating the insulating layer.

Low friction coefficient

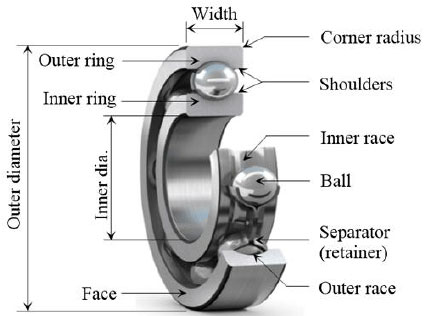

Deep groove ball bearing is widely used in industrial machinery, automobile wheels, and appliances. It consists of a pair of ferrules and a group of retainers. These components combine to provide a solid support for radial and axial loads. In addition to low friction coefficient, the deep groove ball bearing also has a high limit speed and a high rate of load transfer. Low friction coefficient and long lifetime are some of the benefits of this type of bearing.

Quick limit speed

High-speed applications create friction and heat that can lead to early breakage. These failures can cause lost revenue, unplanned downtime, and waste of resources. For these reasons, it is important to limit operating speeds and consider the Speed Limit Factor when selecting a bearing. Here are some considerations to keep in mind to get the best performance from your deep groove ball bearings. Let's look at each one.